Contact us now and start your efficient machining journey!

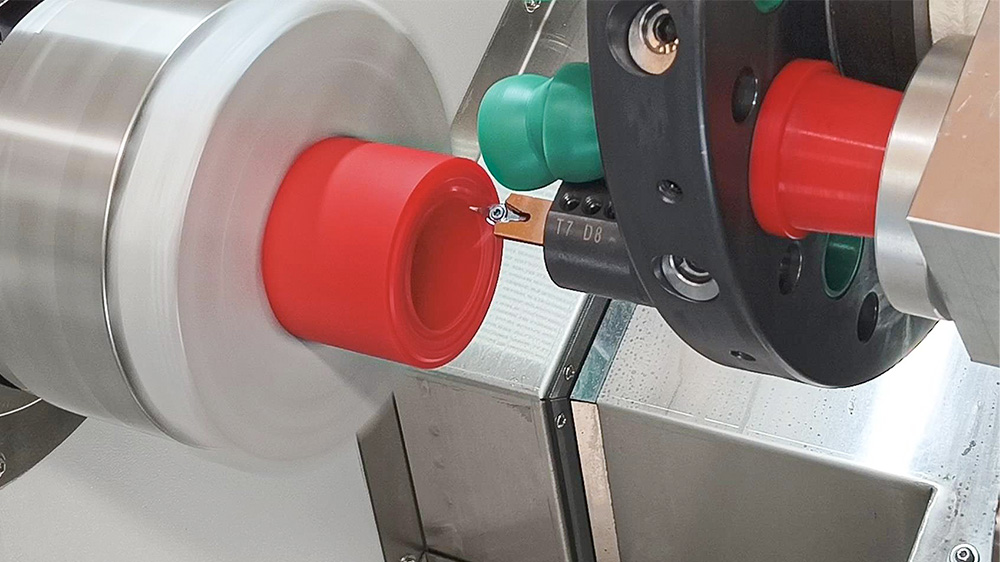

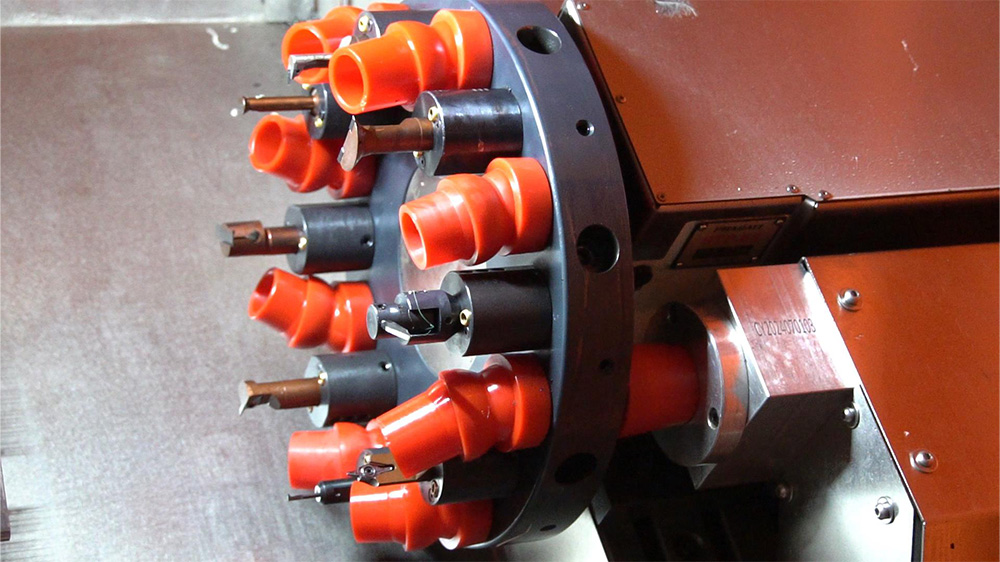

In the field of seal ring machining, product models and dimensions vary widely. Traditional methods require frequent tool changes and repeated adjustments, which are time-consuming and inefficient. Our Seal Making CNC Machine, equipped with a built-in process optimization system, allows you to simply input the part size, and it will automatically recommend the suitable tool set. This ensures quick changeover and higher productivity.

●Fast Changeover: Just enter the part dimensions to receive recommended tool settings, minimizing manual trial and error.

●Efficient Batch Production: Ideal for manufacturers handling multiple sizes and frequent production changes.

●Stable Accuracy: Ensures both surface finish and dimensional precision in seal ring profiles.

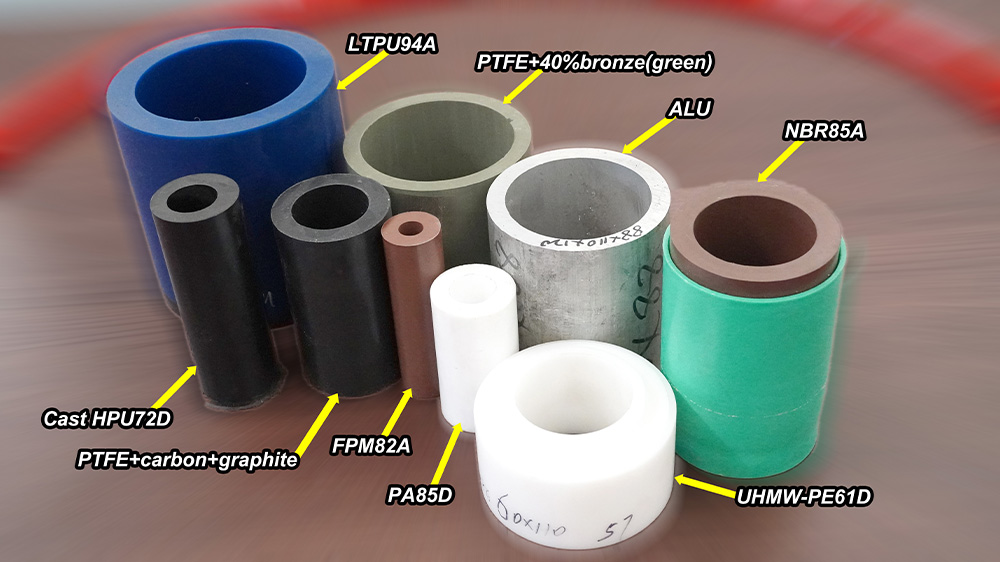

●Wide Material Compatibility: Capable of machining seal rings made of rubber, plastics, and composite materials.

The lathe can handle a wide range of seal ring materials efficiently, including:

●Rubber

●Engineering plastics (Nylon, PTFE)

●Metals (stainless steel, aluminum)

●Composite materials

By simply inputting the part dimensions, the system will recommend the right tool set based on the machining process. This reduces reliance on operator experience and streamlines production.

●Hydraulic and pneumatic sealing components

●Automotive and mechanical parts

●Energy and chemical equipment

●Medical device sealing elements

Choose our CNC seal ring machining lathe for more flexible, faster, and more reliable production!

Do you want to know more?

Please click to browse the electronic catalogue