Contact us now and start your efficient machining journey!

In today's competitive manufacturing landscape, efficiency, precision, and flexibility are no longer optional—they are essential. Whether you are producing high-volume small components or complex multi-feature parts, choosing the right CNC machine configuration can make a critical difference.

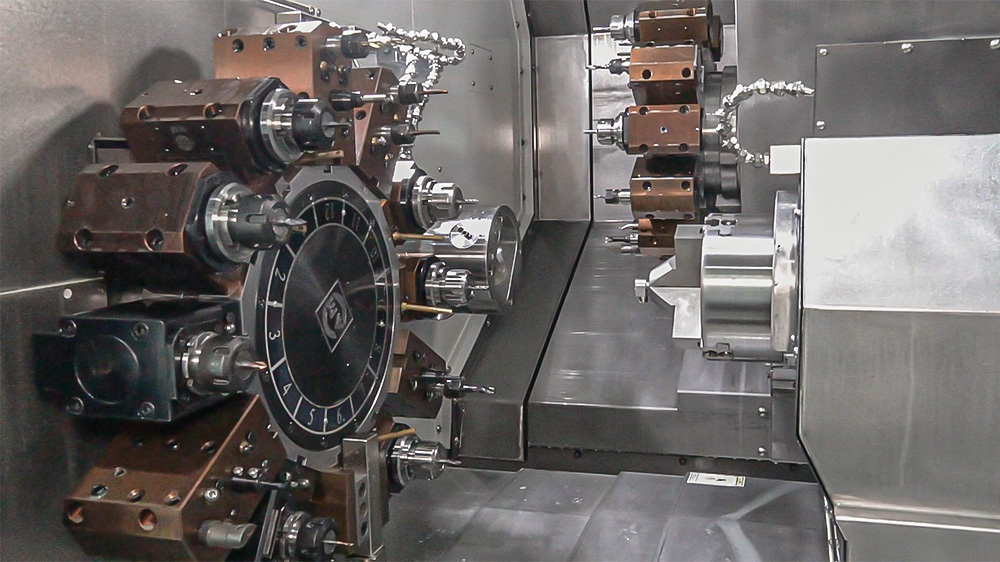

1. Turret CNC Lathes: Reliable and Cost-Effective

Turret CNC lathes remain the backbone of many workshops due to their versatility and reliability. Equipped with a multi-station turret, these machines can perform multiple turning operations in one setup, reducing tool changes and improving production efficiency.

Key Advantages:

●Simplified programming and operation

●High repeatability for batch production

●Cost-effective for small to medium-sized components

Despite their advantages, conventional turret lathes can be limited when tackling complex parts with multiple features or when simultaneous front-and-back machining is required. This is where dual-spindle dual-turret centers shine.

2. Dual-Spindle Dual-Turret Machining Centers: Double Productivity, Double Precision

Dual-spindle dual-turret CNC machining centers are engineered for high-efficiency production. By combining two spindles and two turrets, these machines can process the front and back sides of a part simultaneously or operate multiple tools at once, cutting cycle times dramatically.

Why choose dual-spindle dual-turret centers:

●Simultaneous front-and-back side machining

●Flexible tool combinations for complex geometries

●Increased throughput without sacrificing precision

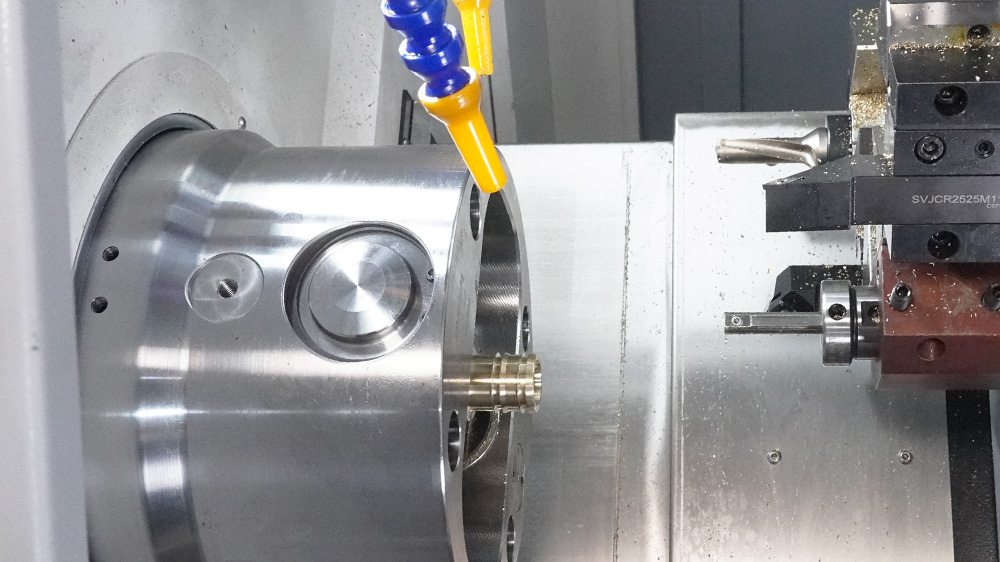

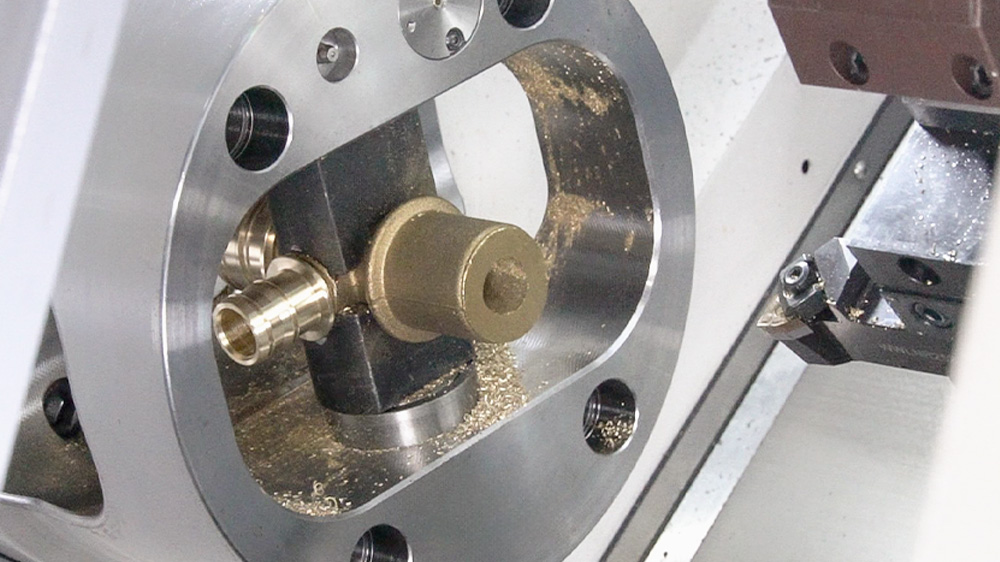

3. Enhancing Capability with Indexing Chucks

Pairing CNC machines with an indexing chuck (rotary indexing fixture) further expands production possibilities. Unlike standard chucks, indexing chucks allow the workpiece to rotate to precise angular positions, enabling multi-face machining without removing and re-clamping the part.

Benefits of indexing chucks over standard chucks:

| Feature | Indexing Chuck | Standard Chuck |

| Angular Positioning | High precision (e.g., 0.01°) | Limited or manual |

| Multi-Face Machining | Easy and repeatable | Requires multiple setups |

| Production Efficiency | Reduced cycle time | Longer, less efficient |

| Part Accuracy | Consistent | Higher risk of alignment errors |

By combining dual-spindle dual-turret machines with an indexing chuck, manufacturers achieve unparalleled efficiency and precision for multi-feature components.

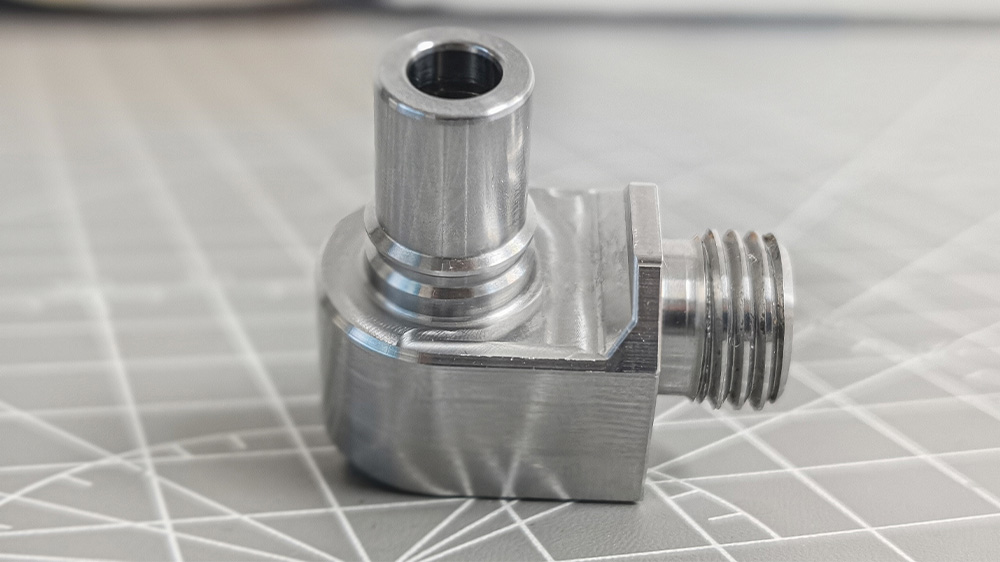

4. Application Scenarios

Industries benefiting from this setup include:

●Automotive components (precision shafts, fittings)

●Medical devices (small implants, surgical instruments)

●Electronics and connectors (multi-featured metal parts)

For instance, a small stainless-steel component requiring front-back threading and side drilling can be completed in one uninterrupted cycle, minimizing handling errors and maximizing throughput.

5. Why This Combination Makes Sense

1. Time Savings: Simultaneous multi-side machining reduces overall cycle time.

2. Precision: Less re-clamping ensures tighter tolerances and higher part quality.

3. Flexibility: Adaptable to a wide range of part geometries and production volumes.

4. ROI: Increased efficiency and reduced labor translate directly into cost savings.

Investing in the right CNC machine and fixturing system is not just about acquiring a tool—it’s about unlocking the full potential of your production line.

For manufacturers targeting efficiency, precision, and high-volume capabilities, combining dual-spindle dual-turret CNC machining centers with indexing chucks is the optimal solution. From reducing setup time to achieving multi-angle machining in one pass, this approach provides tangible advantages over conventional turret lathes and standard chucks.

Whether you are upgrading your production line or starting a new project, consider this combination to elevate your manufacturing capabilities and stay competitive in the global market.

Do you want to know more?

Please click to browse the electronic catalogue