●Machining Max. dia.20/26 /32mm,length 240mm workpiece.

●Temperature compensation program improve workpiece precision when cold start.

●Chip breaking function by low frequency vibration technology.(optional)

●Cut-off tool breakage detector.

PRODUCT INTRODUCTION

- FEATURES

- TECHNICAL SPECIFICATION

- CONFIGURATION

- SAMPLE MACHINING

|

|

| |

| Item | Unit | ST-203 | ST-263 | ST-323 | |

| Capacity | Max. machining dia. | mm | Φ20 | Φ26 | Φ32 |

| Max. machining length | mm | 240 | 240 | 240 | |

| Max. drilling dia.of front side | mm | Φ10 | Φ10 | Φ13 | |

| Max. tapping of front side | mm | M8 | M8 | M8 | |

| Spindle through-hole dia. | mm | Φ23 | Φ28 | Φ38 | |

| Control system | Mitsubishi E80 | Mitsubishi E80 | Mitsubishi E80 | ||

| Spindle | Machine power | kw | 7 | 7 | 7 |

| Main spindle power | kw | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | |

| C axis indexing | ° | 0.001° | 0.001° | 0.001° | |

| Main spindle max. speed | rpm | 8000 | 8000 | 8000 | |

| feedrate | m/min | 32(Y1/Z1);20(X1) | 32(Y1/Z1);20(X1) | 32(Y1/Z1);20(X1) | |

| feed motor power | kw | 1 | 1 | 1 | |

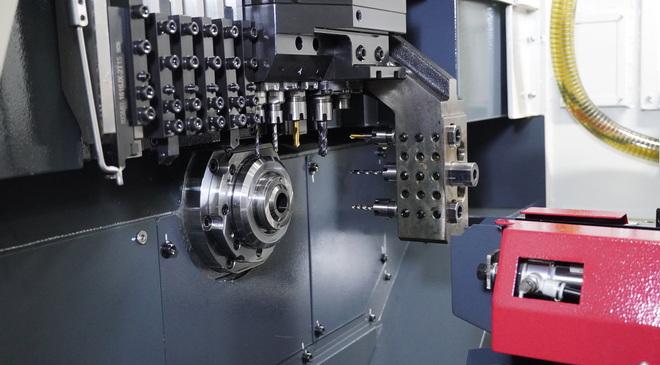

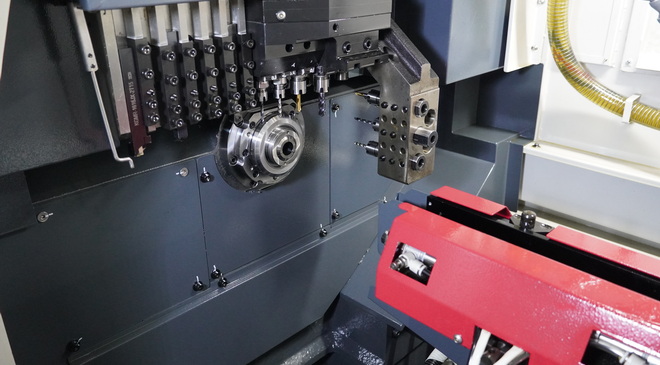

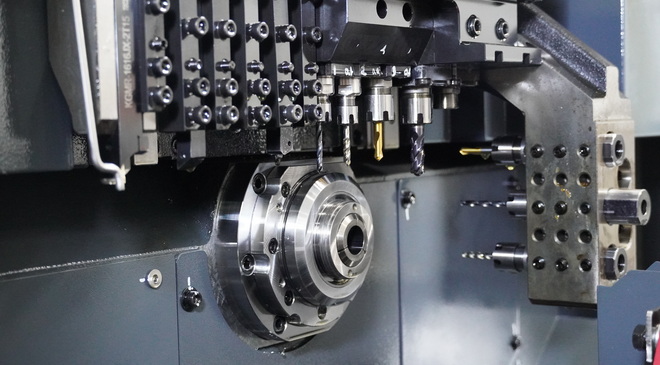

| Front side tool post | Gang turning tool | 6×□12 | 5×□12+1×□16 | 6×□16 | |

| Side rotary tool (II /III model) | 2×ER11+3×ER16 | 2×ER11+3×ER16 | 3×ER16+1×ER20 | ||

| Max. drilling dia. | mm | Φ10 | Φ10 | Φ13 | |

| Max. tapping | M8 | M8 | M8 | ||

| Side rotary tool speed | rpm | 5000 | 5000 | 5000 | |

| Side rotary tool power | kw | 1 | 1 | 1 | |

| End face fixing tool qty. | 5×ER16 | 5×ER16 | 5×ER16 | ||

| End face fixing tool dia. | mm | Φ10 | Φ10 | Φ13 | |

| End face fixing tool tapping | M8 | M8 | M8 | ||

| Other | Machine net weight | kg | 1800 | 2000 | 2100 |

| Machine size (L×W×H) | mm | 2100×1480×1780 | 2100×1480×1780 | 2100×1480×1780 |

STANDARD CONFIGURATION:

Mitsubishi E80 control system

Main spindle chucking unit

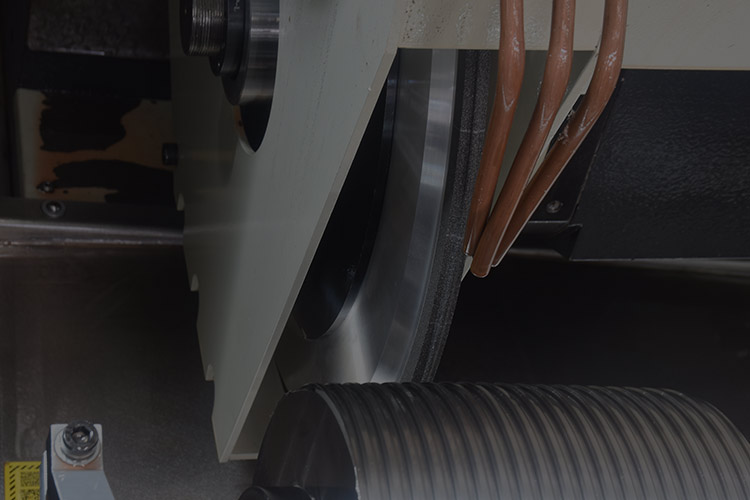

Rotary guide bushing unit

Gang rotary tool driving unit

Coolant unit

Lubricating oil supply unit

Cut-off tool breakage detector

Workpiece receiver

Electical cabinet heat exchange

Work lamp

Chip box

OPTIONAL CONFIGURATION:

High pressure oil pump

Coolant mist collector

Chip conveyor

Bar feeder

Syntec 22TB control system

Mitsubishi E80 control system

Main spindle chucking unit

Rotary guide bushing unit

Gang rotary tool driving unit

Coolant unit

Lubricating oil supply unit

Cut-off tool breakage detector

Workpiece receiver

Electical cabinet heat exchange

Work lamp

Chip box

OPTIONAL CONFIGURATION:

High pressure oil pump

Coolant mist collector

Chip conveyor

Bar feeder

Syntec 22TB control system

En

En Ru

Ru Es

Es Pt

Pt